WILBUR has carved a spot in the competitive watch industry with a mission to create emotionally and technically exciting pieces based on the American pioneering spirit. Jason Wilbur, an award-winning designer, leads the company using KeyShot to create and communicate watch designs that also inspire and captivate. Here, we talk with Jason to learn more about how WILBUR started, his process, and what makes his watches so exceptional.

What sparked the interest in watch design and led to the launch of WILBUR?

What sparked the interest in watch design and led to the launch of WILBUR?

Since I was a kid, I was fascinated with mechanical watches and all things mechanical for that matter. I became most interested in watches when they “became useless” as a time-telling tool. When smartphones arrived, telling time took a back seat to the sculptural and artful function of a mechanical watch. This is when watches became an emotional statement rather than a tool and this opened up huge opportunities in terms of creating new interpretations of what a watch could be.

My career as a car designer led me to explore product design as well. In order to keep my design-mind fresh I would reimagine everything from musical instruments to watches. This exploration really started to gain momentum after I graduated from Art Center College of Design and had been in the auto industry for a few years. I spent a lot of time designing watches using the same processes I would use to design a concept vehicle and that led to a whole new idea of creating an American watch brand that really pushes the limits of design and engineering while also being solidly influenced by the Southern California car culture and the automotive R&D I was immersed in. One of the first watches I designed was what later became the Devon Tread 1 watch. (I sold the design rights to Devon in order to get the watch produced.)

Designing watches became a sort of creative outlet for me and for several years I designed watch concepts with the idea that I would eventually have to create my own brand to realize the watches in physical reality. I knew my take on watches was a rebellious one and the only way I would be able to really be able to break into a fairly conservative industry would be to do it on my own. This reality gave birth to the WILBUR brand.

What’s unique about the design process or approach to a product at WILBUR?

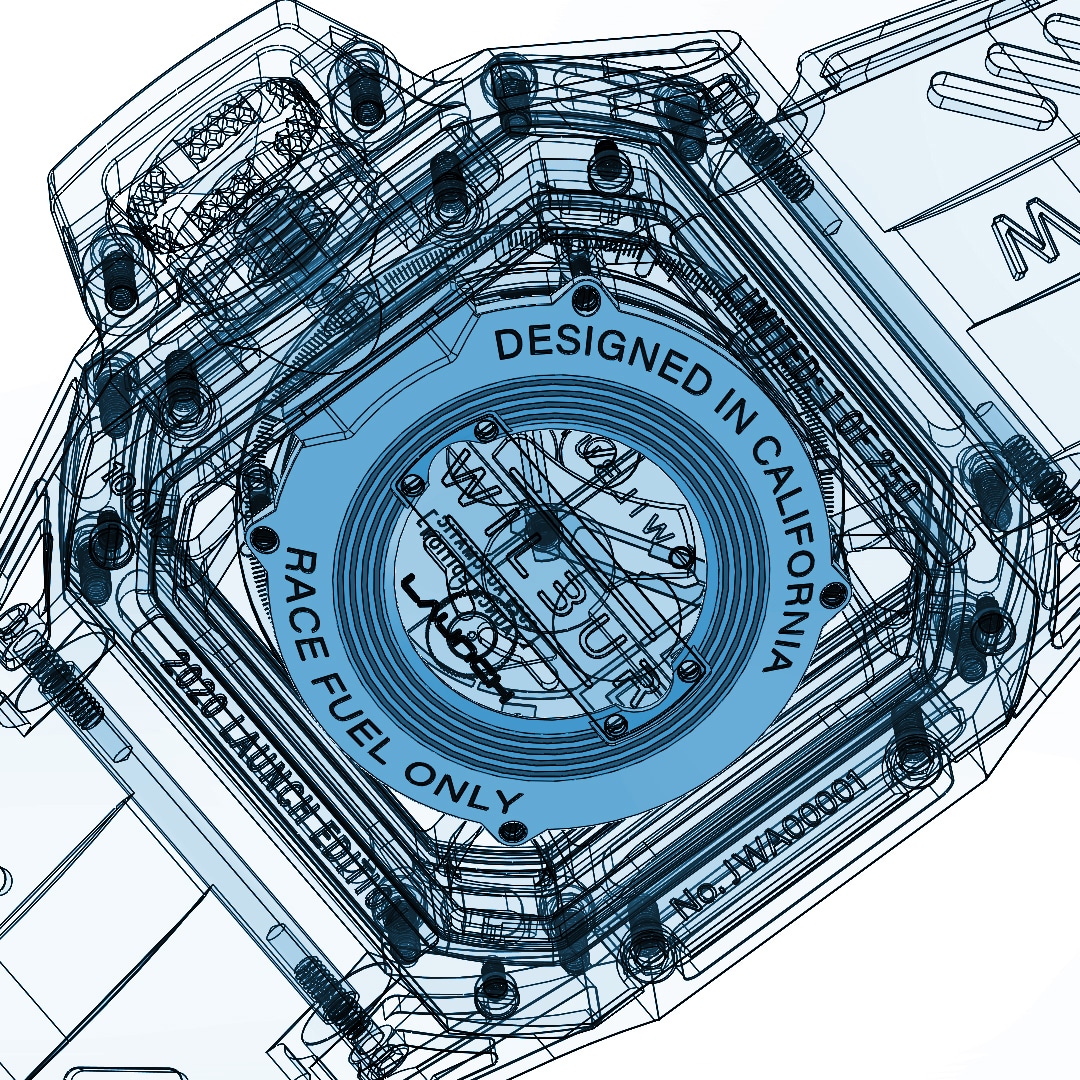

WILBUR is a design driven brand. I don’t let industry processes and expectations drive the product. All designs are developed using modern industrial design and automotive R&D methods. My goal is that each piece must have a big personality and make a statement. We are not interested in creating products derivative of anything else on the market at WILBUR. I design all watches myself and I build them in SOLIDWORKS to avoid misinterpretations. I 3D print models to verify the size, feel and proportions of each watch and to refine the ergonomics as well. We like to say that if a watch design isn’t at least a little difficult to produce, it’s not worth producing.

What is the primary 3D modeling software at WILBUR?

I use SOLIDWORKS primarily for all of my watch design work. Being able to quickly create rough ideas as well as refining designs down to their production dimensions is what I love about the flexibility of SOLIDWORKS. It is an artistic tool and serious engineering machine all in one.

Where in your process is KeyShot used?

I use KeyShot throughout the entire creative process, from validating rough design ideas and communicating subtle finishes on products for the factory to final photographic renderings used in marketing materials and animations. I have used KeyShot for every single watch I have created, most recently, the WILBUR Launch Edition line of watches.

Overall, how has KeyShot helped save time, money and/or improve quality?

KeyShot saves me piles of time in my creative process. The ability to quickly visualize ideas and see the materials, colors and proportions with photographic realism allows me to make creative decisions on the fly. I no longer need to produce as many prototypes or use traditional photography which typically increases costs and slows down the overall process. KeyShot helps massively when it comes down to improving product quality on the production side. Making luxury products is about exceeding expectations; product finishing and manufacturing needs to be perfect and needs to match the design intent 100%. Using KeyShot images to show the factory our design intent leaves no room for error.

What advice would you give to others interested in design, or launching a business or new product?

The reason why most designers put off starting their own business or launching a product is because they have been told too many times that designers and creative people, in general, aren’t good at business. This is simply not true. There are countless examples of designers and creative people creating massively successful businesses. The first step is to start. If you have a big idea, start. If you are hungry and full of passion, start. Start anywhere. Just start. The next step is to surround yourself with talented people who will support you. There are things you will not be good at; find the people that are good at those things and surround yourself with them. The final step is to never give up. We hear that all the time from people, but it’s true. No one has ever been successful by giving up.

See more at wilburco.com/