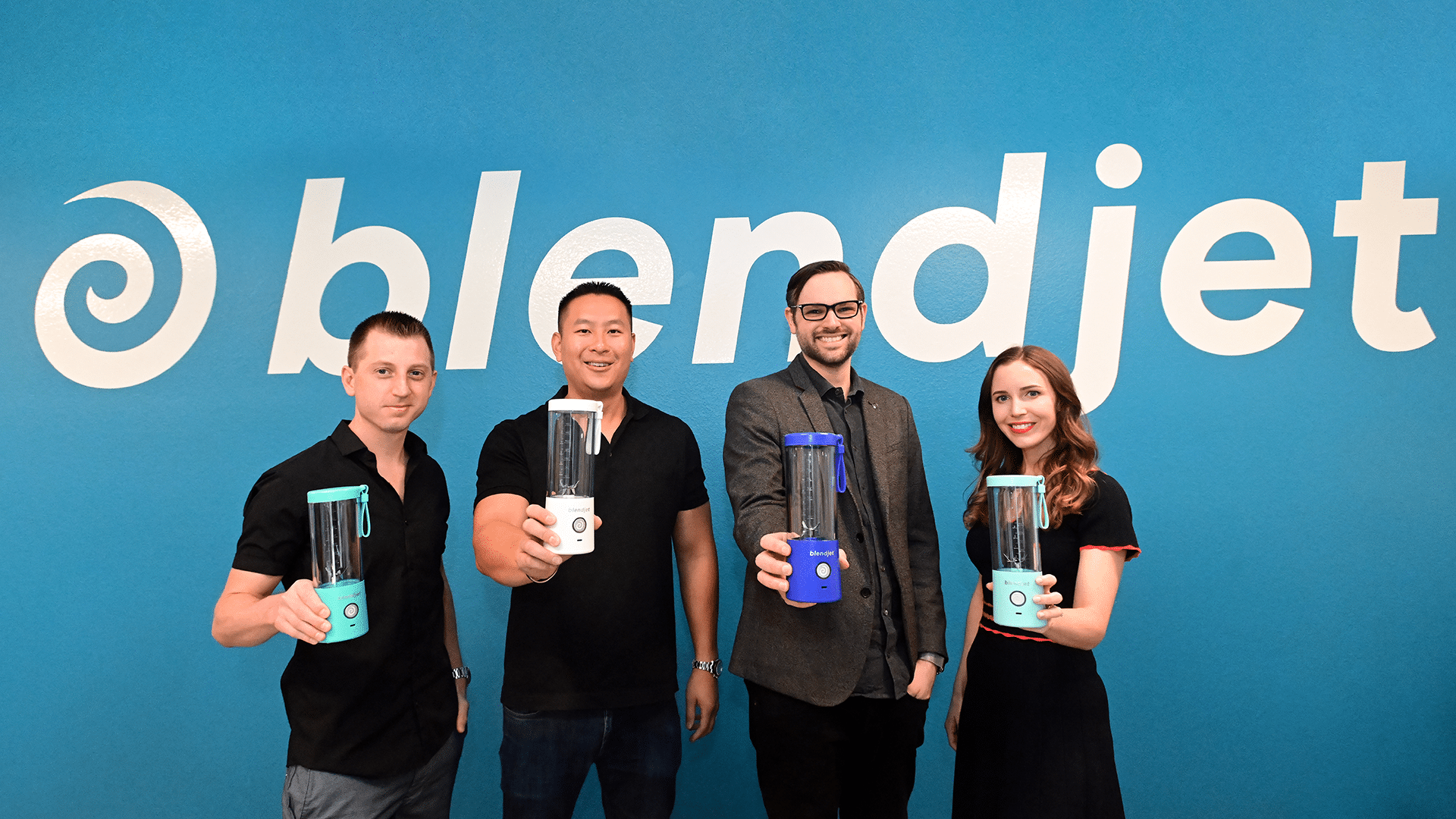

When you think of life-changing products, there may be a handful that comes to mind. However, when you look at products that influence lifestyle in such a way that it affects health, habits, and drops small amounts of joy throughout the day, there’s one at the top of the list. You may have heard of BlendJet but there’s much more to this unassuming pint-size blender than you may realize. It’s a success story on multiple levels, from its startup and selling millions of units to its design and life-altering appeal. Here, we talk with Co-Founder and CEO, Ryan Pamplin, about how BlendJet started, what’s so unique, and how KeyShot has been instrumental in its success.

How BlendJet was Born

The short story is that I slammed my head into a concrete pillar. The long story is that in true Silicon Valley style, I was watching my Tesla park itself in a tight spot in my garage. I was also in a rush, so I was running backward at the same time while looking back, then flipped around quickly, and slammed full speed into the pillar with my head. I ended up with a serious head injury that put me on medical leave for a year, during which time the company I’d been a part of was acquired.

The short story is that I slammed my head into a concrete pillar. The long story is that in true Silicon Valley style, I was watching my Tesla park itself in a tight spot in my garage. I was also in a rush, so I was running backward at the same time while looking back, then flipped around quickly, and slammed full speed into the pillar with my head. I ended up with a serious head injury that put me on medical leave for a year, during which time the company I’d been a part of was acquired. Why has BlendJet resonated so much with people?

Why has BlendJet resonated so much with people?

BlendJet gives you the superpower to make and enjoy a smoothie anytime, anywhere. Our customers love to use their BlendJets at work. I think the choice is often between a McDonald’s drive-through and a fresh smoothie. The convenience of a quick and healthy BlendJet smoothie is compelling to people, so much so that we have over 1 million customers across 195 countries.

What’s unique about the design process at BlendJet?

We don’t involve many people in the early stages of the design process. We have one amazing design leader, William Gordon, who previously led design at CamelBak. I will briefly discuss a concept with our leadership team, get buy-in, pitch my vision to William, he sketches it, we iterate, then William models it in 3D and creates photorealistic renders in KeyShot to show the team for feedback. We keep iterating on the design until the whole team is super excited by it. We make 3D prints to evaluate how it feels, tweak the 3D and then hand it off to our mechanical engineer to make the design functional. Finally, our VP of Ops, Brian Zuk, oversees the long and complex journey of taking our design from 3D files to mass manufacturing, which involves trips to our factory and a lot of collaboration with factory engineers, our mechanical engineer, and William.

Where in the design process is KeyShot used?

We use KeyShot early on in our design process to communicate the vision of the product we’re creating in a way that non-3D people can easily understand. I’ve found most people can’t look at a wireframe or low fidelity SolidWorks renders and judge a design fairly. KeyShot ends up saving us a ton of time and money down the road since the early renders accurately depict what the physical product will look like before we even make it. This also provides a great source of truth for the factory to understand what we want to achieve.

How did visuals play a part in the run-up and launch of BlendJet 2?

KeyShot renders have been essential to our design process for BlendJet 2. With BlendJet One, it was only used for marketing renders. KeyShot is so easy to use that I’ve even made renders myself, testing out many patterns and color options. I poll our team and customers on which they like best, and their feedback determines what we make.

The big takeaway is, don’t show non-designers SolidWorks renders because they won’t be impressed no matter how good the design is. Make KeyShot renders first, then get feedback.

Imagine the freedom of being able to go anywhere and blend your favorite smoothies, shakes, margaritas, or baby food without the limitations of a regular blender. BlendJet 2 is the Next-Gen Blender. It’s on another level!

- Big Blender Power (5X More!)

- 33% More Capacity (16 oz)

- USB-C Port

- Pulse & Lock Modes

- Water-Resistant

- 15 Blends Per Charge

- Same Compact Size

Imagine the freedom of being able to go anywhere and blend your favorite smoothies, shakes, margaritas, or baby food without the limitations of a regular blender. BlendJet 2 is the Next-Gen Blender. It’s on another level!

- Big Blender Power (5X More!)

- 33% More Capacity (16 oz)

- USB-C Port

- Pulse & Lock Modes

- Water-Resistant

- 15 Blends Per Charge

- Same Compact Size

Overall, how has KeyShot helped save time, money and/or improve quality?

We use KeyShot for the product photos on our website, our retail packaging and sometimes even for visuals in our commercials. When we switched from photos of the BlendJet One to KeyShot renders, we increased our website conversion rate and sales by 20%. It’s really difficult to make a product photo look perfect, but with KeyShot it’s easy to get that super clean, Apple-quality product photo that resonates with consumers.

What advice would you give to others interested in launching a product?

Ask yourself if you’d buy the thing yourself, and how much you’d pay for it. Ask other people the same. Validate that you’ve got real demand, and try to understand who your target audience is. Ideally, you’re building something to solve a problem you have, and it’s a pain point that many other people have, too. Make sure others aren’t already doing what you’re doing, or at least that they’re not doing it well, otherwise, it’s going to be an uphill battle. If your product sells for $99, you’re going to need to manufacture it for a tiny fraction of that price, because the bulk of your selling price will go into customer acquisition, shipping, and other overhead. You also need to ensure you’ve got enough margin for retailers which is typically 40% – 60%. You can’t avoid brick and mortar because it still captures 90% of consumer spending. If your product is too expensive to manufacture and sell at a compelling price, then your concept probably won’t take off.

See more at blendjet.com